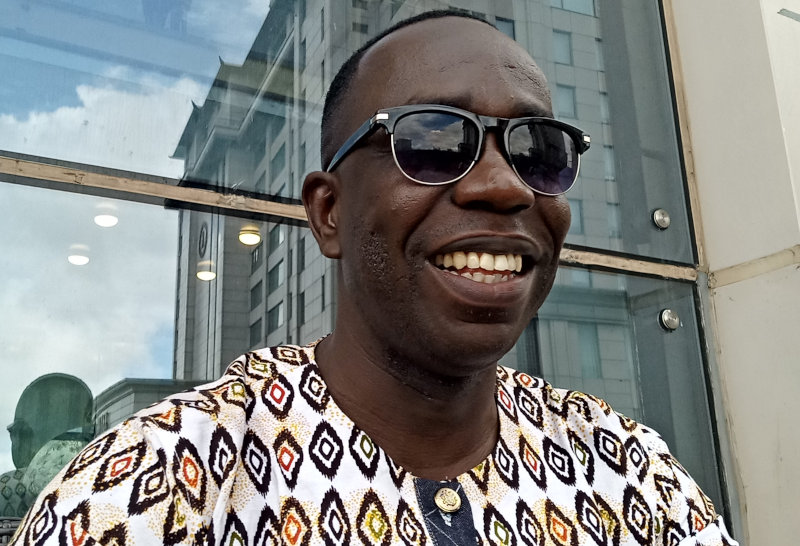

Akwasi Osei-Bobie Ansah

Through observation skills and an innate interest in understanding the science behind things, Ghanaian entrepreneur Akwasi Osei-Bobie Ansah found the building blocks for a profitable business idea.

“I heard farmers talking about declining yields, even with excessive use of inorganic fertilisers. As I had a science background, I figured the soil might be acidic; so irrespective of the amount of inorganic fertiliser used, they would not get the desired results and it would further deteriorate the soil,” Ansah says.

Ansah had obtained a teaching degree after school but was always more interested in agriculture. Back home in the village where his parents had their fields, he had observed higher crop yields in areas where cocoa shells were left to decompose. He realised that this waste product from Ghana’s biggest export product could be channelled into making an organic compost or fertiliser.

In 2009, while working at the National Board for Small Scale Industries (a government agency in Ghana) as part of his national service, he pitched this idea at a World Bank competition looking at innovative ways to manage waste.

Ansah had also researched other materials, along with the cocoa shells, that could be used to formulate an organic fertiliser to improve the soil and provide nutrients for the plants. All of the materials used in his final formulation were sourced locally, as they still are today.

By the time the competition winners were announced in 2011, and Ansah placed third, his product was already being sold in the market.

Today, Farmers Hope products – the original organic fertiliser (named Asaase Nofosuo) and an organic pesticide and fungicide – is sold in both Ghana and Burkina Faso. The company also has a liquid fertiliser currently on trial for certification.

Finding finance

Initially, Ansah was the company’s only employee and he manufactured the fertiliser manually. His first major supplier of cocoa shells was ADM Cocoa, a company later acquired by Olam.

Two years after producing his first bag of fertiliser, however, Ansah acknowledged he would have to become more aggressive in his marketing. He reached out to one of the bigger companies that provided agricultural input products to farmers.

He secured a meeting with the company’s executive team and presented his samples.

“I explained I could produce the very best fertiliser for them. However, the CEO looked at the product and said it was no good and that I should go.”

As he was leaving, Ansah emptied his sample into the company’s plant pots and beds.

“A week later, they started seeing the results in the plants and after the security guard told them it was thanks to my product, I received an order for 200,000 bags.”

At his capacity of 10 bags a day, Ansah knew he’d never be able to fulfil the order but boldly agreed. Armed with a contract and a small upfront payment of $1,000, he approached the Agricultural Development Bank in Ghana. The bank provided a loan to procure the required machines to push up production volumes.

Although the contract deadline was still too ambitious, Ansah did manage to provide enough quality product by the agreed time for the client to allow an extension of the delivery of the full order.

In that same year, Farmers Hope hosted an official launch of its product and, by December 2012, the company held its first meeting with Growth Mosaic, a USAID FinGAP Business Advisory Service provider. Growth Mosaic helped Farmers Hope streamline its business and facilitated financing from Acumen Fund West Africa to further scale up production in 2016.

A bag of Farmers Hope’s Asaase Nofosuo fertiliser.

Acumen disbursed around $500,000 to Farmers Hope to procure equipment. Ansah explains finding the right machines from existing suppliers was difficult as his process differed from that of other organic fertiliser manufacturers.

Once he received the machinery, it took a further three years to fine-tune the equipment to suit his unique production process.

“I was not about to change my process to fit the machines. Fortunately, we now have local engineers who understand what we need and can provide the machines,” he says.

The distribution struggle

One of the lessons Ansah has learnt is to find trustworthy distributors.

Some distributors would take payment from the farmers, but would not pay Farmers Hope. He tried to recoup some of the money via the courts but had to make the difficult decision to sever ties with specific distributors, even major players in the market.

“It did affect our sales but we are better off working with distributors who pay on time. We now get calls directly from farmers who cannot find our product because we refused to supply those distributors who don’t pay us. The farmers have started to group themselves to place orders directly,” says Ansah.

When Farmers Hope does find a trustworthy distributor, the results speak for themselves, adds Ansah. The company has a regular consignment of about 100,000 bags to Burkina Faso through one such distributor partner.

Expansion plans

Farmers Hope has received queries from other countries – specifically Côte d’Ivoire, Togo and Benin – but before contracts can be put in place, Ansah wants to increase the production capacity at the new factory premises in Kumasi.

The company has already made part-payment on the land and cleared it; construction should start by the end of January 2021. Farmers Hope will not accept any new orders until the facility is complete as it has had to vacate its previous rented premises. “We have enough stock to last until the second quarter of this year.”

Ansah wants to equip the new factory with three locally manufactured machines, each capable of producing 400 bags of fertiliser an hour. This equates to 6,600 per day, a massive boost from the current 600 per day.

Acknowledging that sometimes the promised capacity does not materialise, Ansah says even 200 bags per hour extra would be an improvement.

Farmers Hope is awaiting final certification from the Ghana Cocoa Board (Cocobod) as an approved product. Once this is received, the company can supply Cocobod directly to distribute to cocoa producers in the country.

Although this would be a big market for Farmers Hope, Ansah is cautious and will carefully consider the volumes required by Cocobod before committing.

“We won’t rush into contracts as we have to be 100% certain we can supply; we cannot fail them.”

Ansah would also like to invest in broadcast advertising in the coming year, having seen that a presence on radio and television supports brand acceptance by the country’s farmers.

Farmers Hope is still negotiating funding for the completion of the factory and this planned marketing drive. It is hopeful the Cocobod certification will be the deciding factor for a potential funder that has shown interest.

Farmers Hope CEO contact information

Contact details are only visible to our Monthly/Annual subscribers. Subscribe here.